OFFSET PRINTING

This printing technique is particularly well suited to handling large volumes in a fast and highly accurate way.

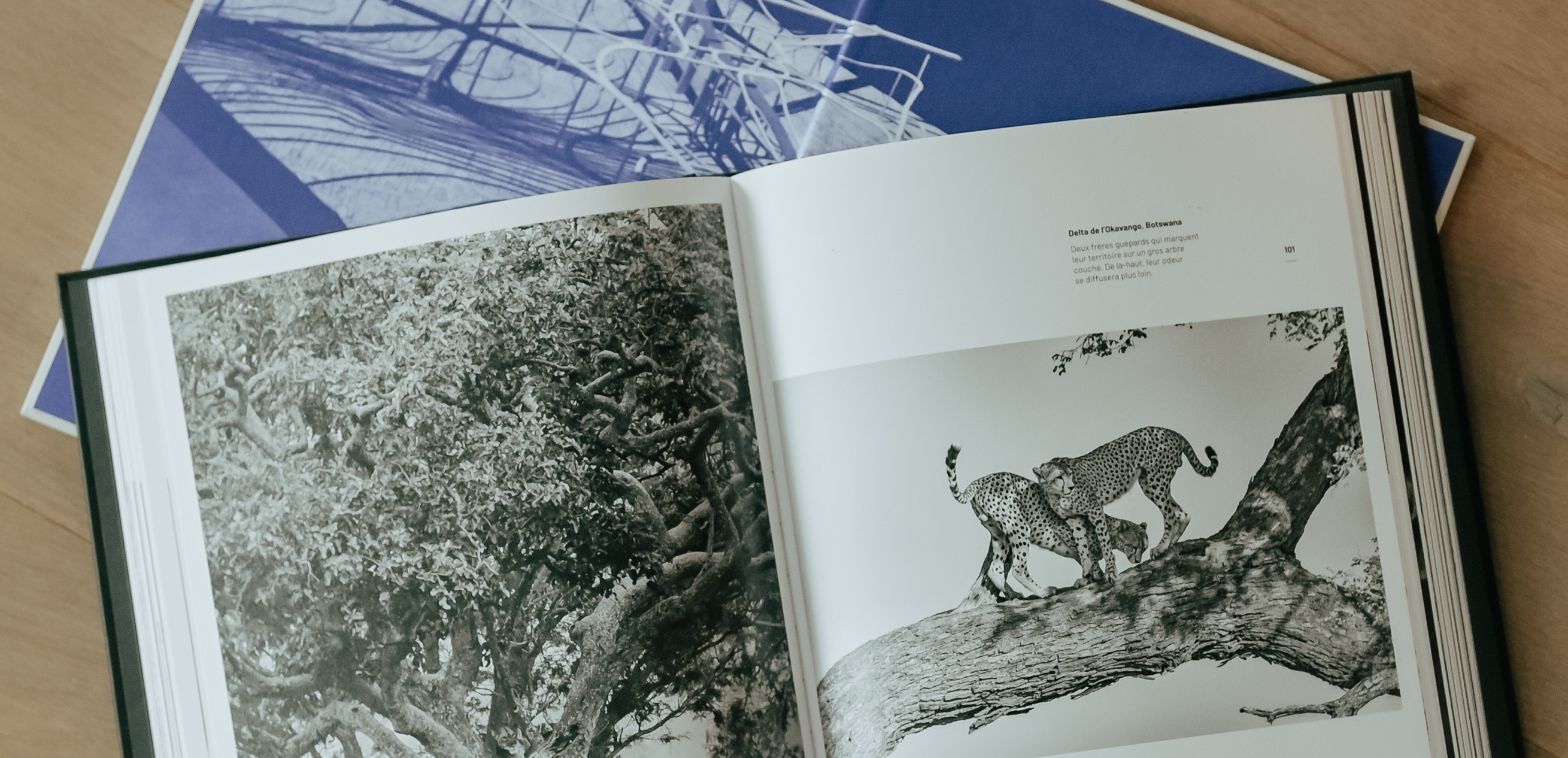

It is ideal for medium and long runs, as well as for any projects that require faithful reproduction of colours, images and fine details, with a very high level of sharpness

(comics, photo books, art books, coffee-table books, etc.).

Our offset pressroom is state-of-the-art and fully dedicated to book publishing.

With 4 presses in 72x102 and 75x106 formats, all perfecting presses, our equipment enables us to handle short, medium and longer runs with optimum quality and high efficiency.

Our presses also allow us to meet a wide variety of project types and technical requirements, for results that are always tailored and as high-quality as possible:

Printing

conventional &

LED-UV

Printing Black, 2-colour,

4-colour process, PANTONE®

By investing in modern and increasingly automated presses, we constantly improve our productivity and significantly shorten average lead times.

We have chosen sheetfed offset printing to guarantee the best possible print quality and the finest rendering of your text, illustrations, halftones and very fine screens.

Because the Sepec group combines both offset and digital printing equipment, we can print some book covers in offset while the inside pages are printed digitally, so you benefit from the best of both worlds!

FOCUS ON LED-UV OFFSET PRINTING:

THE VERY BEST OPTION FOR YOUR MOST DEMANDING PROJECTS AND FOR SUPERIOR RESULTS ON MATT AND UNCOATED PAPERS.

LED-UV printing uses highly reactive inks that cure instantly under UV light.

The ink is fixed on the surface of the sheet, greatly reducing dot gain and enhancing colour intensity, black density, gloss, sharpness, detail and the overall look of your prints.

- - Elimination of set-off and ink transfer risks.

- - No need for anti-set-off powder and/or protective varnish, helping preserve the natural feel and character of the paper.

- - A “straight off press” result that is very close to the final finished product.

- - Greater creative freedom in terms of design and paper choice.

- - An exceptional level of quality and durability.

- - Less paper waste and fewer production rejects (especially thanks to the elimination of set-off issues).